Commercial & Industrial Sprinklers

THE CHALLENGE

Stansted Airport, Essex

During 2014/15 the airside retail complex at London’s third busiest airport, Stansted, was to be completely refurbished. This involved a comprehensive strip-out and reconfiguring of the internal building fabric including the building services. The life safety fire sprinkler system was a vital part of these services and this too had to be stripped back to the main supply pipe downstream of the control valves. From 2013 Vipond Fire Protection, working closely with Carillion, and Jacob’s were tasked with carrying out all operational works whilst the airport remained open for business.

THE SOLUTION

The new installation was based on a complete redesign of the system to LPC regulations Ordinary Hazard Class 3 with BS EN12845 life safety enhancements. This covered 42 new retail units, food outlets and duty-free shops. The airport required two levels of protection due to congestion of services at high level, one at the ceiling soffit and one below the other building services.

THE CHALLENGE

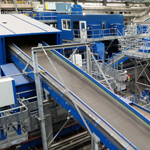

Tovi Eco Park

Tovi Eco Park is part of a 28 year contract awarded to Urbaser Balfour Beatty by both Essex County Council and Southend-on-Sea Borough Council, to manage waste from households across Essex and Southend. The mechanical biological treatment (MBT) facility will treat all residual waste as well as complementing existing recycling and composting services within the region. The client required the contracts to be compliant with industry specific guidance, including Property Damage Fire Prevention for Energy from Waste Plants.

THE SOLUTION

Vipond’s systems design department closely tracked those requirements during the design process to provide the solutions demanded by the client. The scope of works extended to a wide range of fire suppression systems throughout including an automatic fire sprinkler system in accordance with BS EN12845, gaseous fire extinguishing systems to BS EN15004, water spray systems and the provision of water cannon to protect deep bunkers.

Sprinklers

The scope afforded property protection with 6 installations covering over 12 distinct areas throughout the facility. With the exception of the car park these systems were almost entirely to High Hazard category.

IG55 Gas Suppression

Automatic/manual IG55 systems were installed within the Generator room, Transformer room and Electrical Switchrooms. The 300 bar systems are designed deliver a uniform concentration of extinguishing agent throughout the protected areas within 1 minute in accordance with BS EN15004.

Water Cannon

Water cannon and hydrant supply were facilitated by a 45m3 tank with 2 electric Fire Pumps and Jockey pump. The manually operated cannons enable an operator from the security of the control room to direct a water stream at a fire within the bunkers. All in all a comprehensive series of fire protection measures are provided for by a wide range of Vipond suppression systems at Tovi Eco Park. This allows an integrated approach to the fire safety plan and the safety of the premises.

THE CHALLENGE

Asda Stores, Telford

Asda opened its new £4 million store in Telford in February 2014. The shop had many areas which require sprinkler protection. Other than the sales and warehouse roof areas, there were additional areas such as canopies, racks, Home Shopping, ducts and the underground car park. The programming of an installation is always an important factor in a project’s success and this was carefully coordinated by Vipond.

THE SOLUTION

Vipond proposed a fixed automatic sprinkler system, designed in accordance with BS EN12845. The water supplies were provided by a 300m3 storage tank of galvanised cylindrical construction with butyl liner. Hazard classification determined water discharge densities throughout. The fire classifications varied across the premises ranging from ordinary hazard class 2 (OH2) in the car park, OH3 in the sales office and High Hazard in the warehouse areas. A total of 1,628 sprinkler heads were fitted throughout the premises with almost a half of these installed in the underground car park. All sprinklers in public areas were anti vandal. The sprinklers are fed from a network of steel pipe to BS 1387/3601. Vipond’s policy is to fabricate pipework at its LPCB certificated workshop.

THE CHALLENGE

UPM Caledonian

UPM Caledonian is located in Irvine, Ayrshire, The mill has been in production since April 1989 and produces high quality light weight coated paper (LWC) for use in magazine publishing and catalogues and it is the only manufacturer of this product in the UK. The paper making process extends to approximately 1 km long. Recent developments at UPM Caledonian included a modern, fully integrated biomass CHP plant to replace the existing fossil fuel fired boiler. It was felt that an automatic active fire protection system would be advantageous in terms of speed and effectiveness of response and provide a comprehensive fire safety solution to the industrial process.

THE SOLUTION

It was agreed that a comprehensive detection and suppression system would be installed appropriate to the risks. Localised detection sprinkler heads were positioned in the five areas of concern. If a fire occurs in any of these areas, the deluge valve will trip allowing water to flow into the deluge nozzles and discharge foam enhanced water onto the risk. Two Triple IR Flame Detectors were strategically placed. These sense fires very efficiently and have the highest immunity to false alarms.

THE CHALLENGE

Virador, Polmadie

A new recycling and renewable energy centre has changed the skyline along Polmadie Road in the South Side of Glasgow. This facility will have the capacity to recycle 200,000 tonnes of domestic waste annually and replaces a well established waste depot with its landmark towering chimneys. The new plant will divert residual waste whilst releasing recyclable resources from household waste and producing enough energy to power 22,000 households in the city. The complex processes and risk factors required a comprehensive and integrated range of fire protection measures.

THE SOLUTION

Vipond Fire have provided a wide range of system solutions from fire sprinklers at roof level fed from a 1.25 million water storage tank, water monitors, infrared flame detectors and gaseous fire suppression systems. These solutions are tailored to the industrial processes, starting where fuel arrives at Waste Reception in its raw condition and enters the recyclable material process.

THE CHALLENGE

Michelin Tyre Plant, Dundee

Fire Protection to a new purpose built processing and storage warehouse situated next to the existing Michelin Tyre Plant. The new warehouse is primarily being used to store tyres manufactured within the adjoin Michelin Plant facility. The design had to be coordinated to ensure the sprinkler plant was positioned with no impact to the processing of the tyre plant production line, while maintaining the required fire sprinkler coverage to the premises.

THE SOLUTION

Vipond fire protection were contracted to install a new fire sprinkler system complete with new dedicated water supplies and extend the existing fire hydrant system. Vipond used 3D modelling to assist with the design of the fire sprinkler system to ensure the installation was installed and made operational with no impact to the processing and production of the tyre plant.

THE CHALLENGE

ACS Clothing, North Lanarkshire

Fire Protection to an existing 190,000 sq ft storage facility which is being retrofitted to house a fast growing leading provider of dress and formalwear. The facility comprises of a mezzanine storage area and a three storey hanging garment structure which is fully automated. A fire sprinkler system also to be installed within a two storey office area, along with a dry-riser system to the fire escape stairways. The design of the fire sprinkler system had to be fully coordinated around the new mechanical/ electrical plant and equipment, particularly the automated garment conveyor line to ensure no impact to the processing and production.

THE SOLUTION

Vipond fire protection were contracted to install a new fire sprinkler system complete with new dedicated water supplies consisting of a full capacity galvanised cylindrical tank, and twin diesel sprinkler pumps. With a primary installation programme window of four months, Vipond completed the project within the agreed time frame. Vipond used 3D modelling to assist with the design of the fire sprinkler system to ensure the installation was installed and made operational with no impact to the processing and production to the automated garment conveyors. All aspects of the works was completed by Vipond from; Design / procurement / fabrication / installation / testing/ commissioning / demonstration / hand-over and final documentation.

THE CHALLENGE

Abertillery School, Abertillery

The Abertillery School project involved a new build school to replace 2 ageing schools which it was deemed it was uneconomic to repair/ maintain. The new school was located over ground and first floor levels which were angled to generally follow the slope of the hill side. The building was constructed using a steel frame enclosed by traditional brick/block construction with flat roof over throughout.

THE SOLUTION

The sprinkler system is required by Technical Bulletin 221: 2013: 1 and BS EN 12845 2015 to be a ‘wet’ sprinkler system – which means the pipework is charged with water at all times. This is to provide the fastest possible water discharge response time to give the sprinkler system the best chance of suppressing a fire. The sprinkler system on this project was designed to meet the Ordinary Hazard Group 1 classification for a school which requires a discharge density of 5mm/min/m2 over a maximum involvement area of 72m2 for a 30 minutes duration.